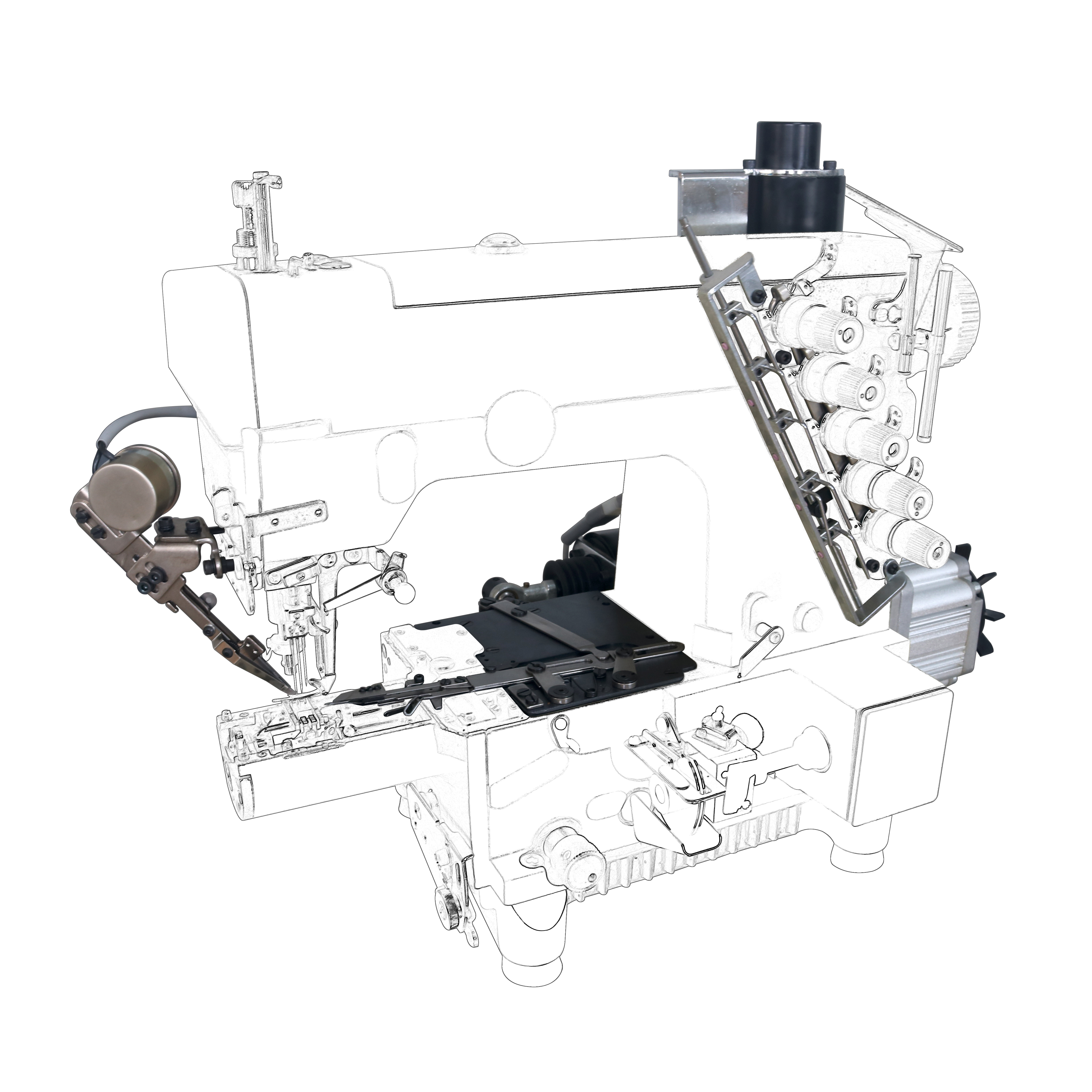

The latest product from Ningbo Dawnsing is the Multi-needle sewing machine thread trimmer, a cutting-edge device that offers advanced features and benefits for industrial sewing operations. This thread trimmer is designed to streamline the sewing process, improve efficiency, and enhance the overall quality of the finished products.

One of the key features of the Multi-needle sewing machine thread trimmer is its ability to trim multiple threads simultaneously, saving time and labor costs. This innovative technology allows for faster production and increased output, making it an essential tool for high-volume manufacturing operations.

In addition to its speed and efficiency, the Multi-needle sewing machine thread trimmer also offers precision trimming, ensuring clean and accurate cuts on each thread. This results in a neater and more professional finish, meeting the high-quality standards expected in the textile industry.

Furthermore, the thread trimmer is equipped with a user-friendly interface, making it easy to operate and control. Its intuitive design allows for quick adjustments and customization, catering to the specific needs of different sewing applications.

Ningbo Dawnsing takes pride in its commitment to providing reliable and durable products, and the Multi-needle sewing machine thread trimmer is no exception. The company's dedication to quality craftsmanship ensures that the thread trimmer is built to withstand the rigorous demands of industrial sewing environments, delivering long-lasting performance and reliability.

The launch of the Multi-needle sewing machine thread trimmer demonstrates Ningbo Dawnsing's ongoing efforts to innovate and improve its product offerings. As the textile industry continues to evolve, the company remains at the forefront of technological advancements, developing solutions that address the changing needs of manufacturers and sewers.

This new addition to Ningbo Dawnsing's product line is expected to make a significant impact on the efficiency and productivity of industrial sewing operations. With its advanced features and reliable performance, the Multi-needle sewing machine thread trimmer is set to become a valuable asset for businesses looking to optimize their sewing processes and elevate their output.

The Multi-needle sewing machine thread trimmer is now available for purchase, and Ningbo Dawnsing is excited to bring this cutting-edge technology to the market. With its proven track record of delivering innovative and high-quality products, the company continues to be a trusted leader in the sewing machine automation industry.

As the textile industry embraces automation and advanced technologies, the Multi-needle sewing machine thread trimmer is poised to play a pivotal role in shaping the future of industrial sewing. Ningbo Dawnsing's dedication to excellence and customer satisfaction positions the company as a reliable partner for businesses seeking to enhance their sewing capabilities and stay ahead of the competition.

In conclusion, Ningbo Dawnsing Sewing Machine Automation Co., Ltd. has once again demonstrated its commitment to innovation and quality with the introduction of the Multi-needle sewing machine thread trimmer. This advanced device is set to revolutionize industrial sewing operations, offering unprecedented speed, precision, and efficiency. With its user-friendly interface and durable construction, the thread trimmer is a valuable asset for businesses looking to optimize their manufacturing processes and elevate their output. As the textile industry continues to evolve, Ningbo Dawnsing remains a trusted leader, providing cutting-edge solutions that meet the changing needs of manufacturers and sewers.